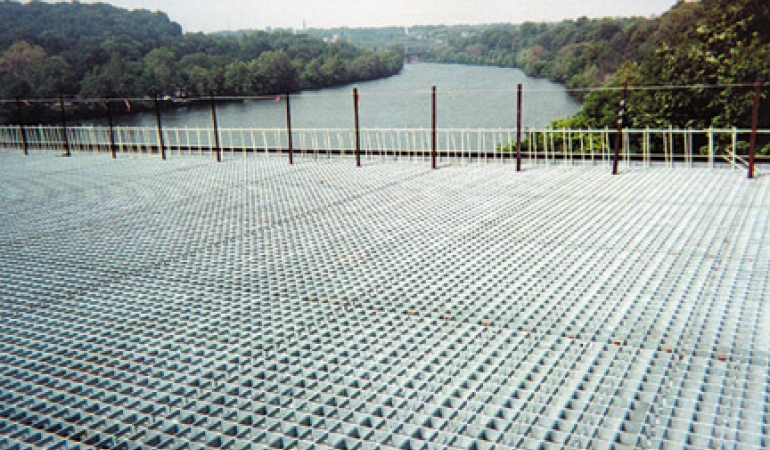

Corrosion protection is especially important for steel embedded in concrete. When reinforcing steel begins to corrode, the surrounding concrete is at risk for cracking and eventual spalling, where pieces may break off and fall on pedestrians, cars, or any other objects below the structure. Galvanized reinforcing steel provides support to concrete structures such as bridges and buildings, while greatly reducing the risk of rebar corrosion.

Galvanized rebar is extremely abrasion resistant due to the intermetallic layers formed during the hot-dip galvanizing process. This means galvanized rebar requires no special handling during transportation and installation. The galvanized coating provides uniform protection and complete coverage to the bars, while also improving bond strength with the concrete once it is poured. In addition to the superior durability and performance of galvanized rebar, many other characteristics, including sustainability and low cost, highlight the wise choice to use galvanized reinforcing steel to strengthen concrete projects.

The AGA, in partnership with IZA and a number of galvanizer companies, offer many resources for specifiers to learn more about the benefits of galvanized rebar. For those seeking continuing education credits, the AGA offers a rebar-specific seminar in three variations: in-person, online, and via webinar. Visit the AGA Continuing Education site to sign up for continuing education credits. Additionally, IZA and the AGA have a selection of free publications relating to rebar. See additional resources below.

View Publications

Visit the Galvanized Rebar site for the latest in research and information.

Download Resources

Discover what the American Galvanizer’s Association (AGA) has to offer.

Discover Real Stories

Scan case studies highlighting galvanized rebar in projects around the globe.